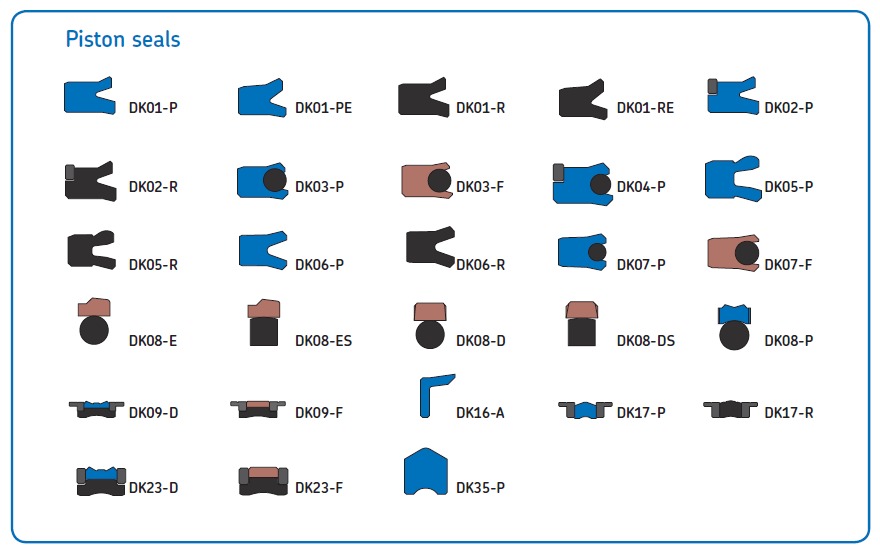

Piston Seals

Piston Seals

Piston Seals are used in hydraulic as well as Pneumatic cylinders for fluid sealing and are designed to ensure that pressurised fluid does not leak across the cylinder head as the system pressure pushes the piston down the cylinder bore.Piston seals maintain sealing contact between a piston and cylinder bore. The moving piston rod generates high pressure on the piston seal which increases contact forces between the seal and cylinder surface. For this reason, the surface properties of the sealing surfaces are critical to proper seal performanceThe choice of piston seal is decided by the way in which the cylinder operates. For a cylinder which is exclusively single-acting, capable of sealing dynamic pressure from one side (unidirectional), it is always best to choose the type of seal designed to provide optimum sealing qualities for single-acting functions.

The best sealing capacity of a double-acting cylinder, capable of sealing dynamic pressure from both sides (bidirectional), is achieved by choosing a double-acting seal.A piston design where two single-acting seals on the piston for a double-acting cylinder are used can easily give rise to a breakdown. The reason is that a very high pressure can be trapped between the seals.Piston seals, both single- and double-acting, can be designed for and used with integrated or separate back-up rings and guide rings.

Typical applications of piston sealare Heavy duty, linear and reciprocating dynamic sealing applications. Capable of handling high pressure spikes, larger running clearances and extrusion gaps.

Fastseal offers a wide range of piston seals that provide the ultimate in leakage control. Piston seals are usually manufactured in our high performance polyurethane, rubber/fabric composite or polyester elastomer.